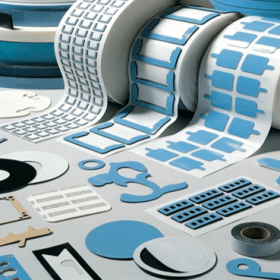

Types of Die Cutting Services

The team at TPC guides customers in selecting the most efficient, precise, and cost-effective die cutting service. Types of die cutting processes we have available in-house include:

- Rotary Die Cutting. Rotary die cutting utilizes cylindrical dies that are attached to a rotary press to precision cut parts and shapes, slit, laminate or perforate materials based on customer specifications.

- Flatbed Die Cutting. Flatbed die cutting, or steel rule die cutting, utilizes a flatbed die cutting press and steel rule dies to convert materials into custom designs and shapes.

We use these dies cutting processes to produce a variety of products, including:

- Foam Tape. Foam tape is typically produced using the flatbed die or rotary die cutting process. We offer open cell, closed cell, and solid rubber foam tape made with various materials like EPDM, vinyl, neoprene, and polyurethane foam for a diverse range of resistances and tensile strengths. We can also cut waterproof foam tape to exact specifications for applications like weatherproofing doors and windows.

- Protective Films. We can produce protective films using both flatbed and rotary die cutting processes. Protective films are used to prevent surface-level scratches on electronics, aerospace technology, and automotive components. They can be die cut into a variety of thicknesses, shapes, and sizes and are capable of offering moisture, heat, and UV resistance.

- Tapes. We die cut tapes, such as 3M VHB tape, using rotary and flatbed methods. This double-sided adhesive tape has industrial bonding strength and resists stress and thermal expansion, along with reducing sound and vibration. It can be cut in a variety of sizes and shapes to suit the needs of any application.

Our Die Cut Packaging and Capabilities

At TPC Converting, we offer in-house die cutting services along with a variety of packaging solutions to meet more precise specifications.

Rotary Die Press

- Lamination

- Liner Change

- Sheeting (Guillotine Cutting)

- Slitting

- Scoring

- Perforation

- Island Placement

- Pneumatic Knock-Out Stations

- Stacking Units

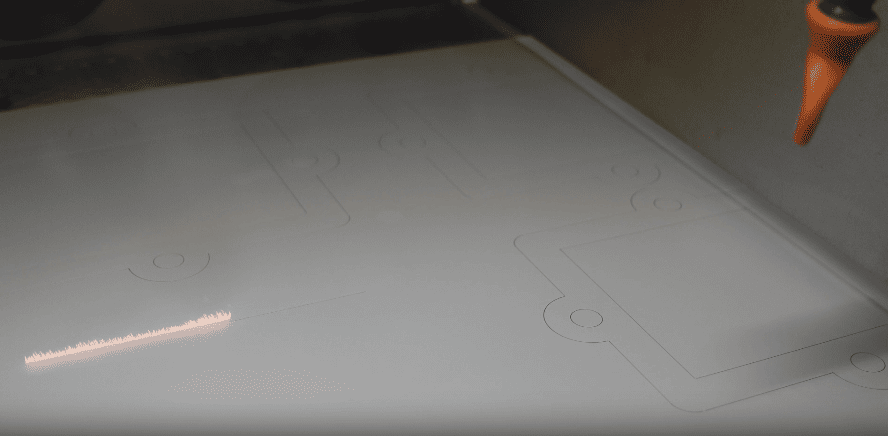

Flashcut Table

- Shapes: to kiss cut linerless material without the use of a cutting die

- Shapes: total cut on a liner or kiss cut on a liner without the use of a cutting die.

- Small quantities for prototypes and/or samples

- Cut sheet materials

- Cut shapes and/or punch holes for gasket-type materials

- Films, tapes with adhesives, rubber materials and foams

- Score, fold

Our rotary cutting, flatbed cutting, and other specialized die cutting services allow us to offer a diverse range of die cut products and materials, including:

- Die cut tape

- Label stock

- Fabric

- Pressure-sensitive materials

- Plastic

- Silicone rubber

- Gasket materials

- Rubber

- Foam & silicone foam

- Ultra-high-molecular-weight (UHMW) polyethylene

- Abrasive materials

- Non-woven materials

- Specialty or custom products

Industries & Applications Served

TPC proudly serves a diverse range of industries with our packaging, printing, and die cutting solutions. These industries include:

- Automotive. As one of the main industries we serve, we provide die cutting solutions for tier 1 and 2 automotive suppliers. The automotive industry counts on die cutting for high-quality gaskets and insulation for high-performance parts. Die cut gaskets ensure a tight, moisture-resistant fit for electronic components, and insulation dampens sound and vibrations while providing resistance to electricity and heat.

- Sign & Graphics. Die cut parts make for eye-catching, three-dimensional signs and graphics for a variety of businesses. Our precise die cutting capabilities allow us to make promotional materials like business cards, POP displays, and restaurant signs in a spectrum of shapes and sizes.

- Electrical & Electronics. Electronic components need precisely cut materials to ensure the best energy efficiency and heat resistance. We can deliver die cut gaskets and foil tape to protect electronics and computer components from interference, vibration, heat, and electrical damage.

- Appliances. Our die cut adhesives, foam, and rubber gaskets help appliances run more efficiently. Appliance manufacturers use die cut foam to reduce vibrations and noise to make products more consumer-friendly. Die cut pieces also make assembly faster and more cost-effective.

- Assembly. Our die cut adhesives help our customers save money on assembly time. Acrylic tapes are strong enough to resist damaging winds on skyscraper windows and are commonly used for smooth decals. We can also deliver die cut foam tapes for reducing vibration and sealing components with precisely cut lengths and shapes.

Die Cutting Services at TPC Converting

Die cutting provides a cost-effective method of delivering precisely cut materials for a broad range of industrial applications. Our in-house die cutting services ensure high-quality products that meet custom specifications. With more than 55 years of expertise working with customers from many industries, our die cutting services provide effective solutions for all needs. To learn more about our die cutting solutions, contact us today.